Flat roofing system performance can be significantly impacted by humidity, especially when it comes to the risk of moisture damage. The roofing industry has responded to this problem by classifying various flat roofing systems according to how well the system can handle various amounts of humidity. These divisions, referred to as humidity classes, help building owners and contractors to choose the best roofing system for their unique requirements.So what are the humidity classes for flat roofing? And how can you be sure to select the right option for your building or premises?

What are the different humidity classes for flat roofing?

Class I, Class II, and Class III are typically the three basic humidity classes used in the roofing industry. Each class has distinct specifications for roofing materials and methods of installation, and each class corresponds to a particular amount of expected humidity.These three classes are:

Class I: Low Humidity

Class I roofing systems are developed to tolerate low relative humidity levels, usually up to 70%. In dry climates with less risk of moisture damage, these systems can be highly effective. Among the materials utilised in Class I systems are single-ply membranes, modified bitumen, and asphalt.

Class II: Moderate Humidity

Class II roofing systems are made to tolerate humidity that is typically between 70% and 80%. These systems are appropriate for use in environments where there is some risk of moisture damage, but not a significant amount. Built-up roofing, single-ply membranes, and modified bitumen are examples of materials that can be used in Class II systems. Fully adhered, mechanically fixed, or ballasted systems are some of the installation methods that may be used for this class of roofing system.

Class III: High Humidity

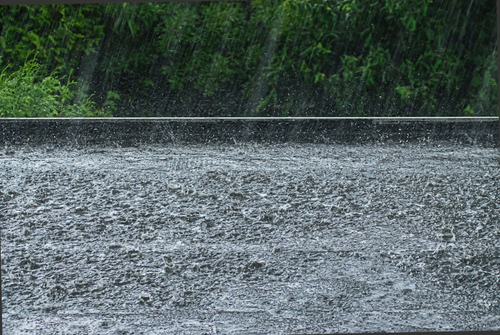

Class III roofing systems are made to endure high relative humidity levels, usually above 80%. In climates where there is a high risk of moisture damage, such as coastal regions or regions with a lot of precipitation, these systems are highly effective. Spray polyurethane foam, built-up roofing, and single-ply membranes are examples of materials that can be used in Class III systems, and these may be fully adhered, mechanically fixed, or ballasted.

Humid conditions and flat roofing

There are other aspects that can affect how well a flat roofing system performs in humid environments ,in addition to selecting the appropriate materials and flat roofing system for the required humidity class for your structure. For instance, preventing moisture development in the roofing system and the nearby building elements requires adequate roofing ventilation. In addition, in order to prevent water from building up on the roof, which could result in moisture damage and other problems, proper drainage is also essential.

To ensure that a flat roofing system is able to withstand the expected levels of humidity, it’s important to work with a reputable roofing contractor and choose a system that is appropriate for the specific climate and building design. Here at Enviroply Roofing we have the expertise and knowledge to create and install the perfect flat roofing system for your requirements. Why not get in touch today to find out more?