Here at Enviroply Roofing, we are the North West’s leading commercial and industrial flat roofing experts. As part of this we provide the highest quality single ply roofing solutions to all manner of properties. As a result, we have produced this guide to everything you should know about understanding single ply roof build up.

What are the key steps for creating an effective single ply roof?

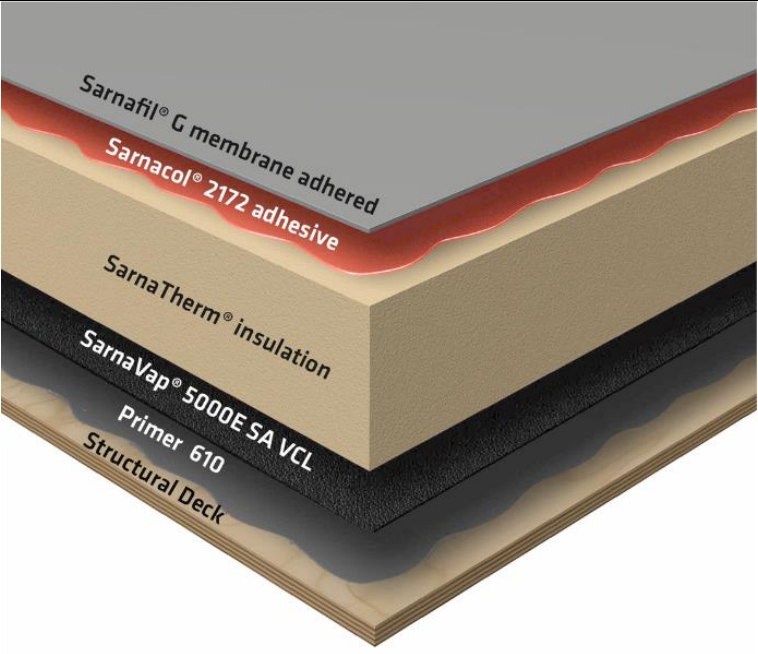

When installing a single ply roof there are a number of different layers that are essential to the long-term success of the roof. These include:

⦁ The structural roof deck

⦁ The vapour control layer

⦁ The insulation layer

⦁ The single ply membrane

The structural roof deck

The basis for any single ply roof is the roof deck itself. This needs to be strong enough for the roof load, and meet all necessary requirements. As part of a roof refurbishment, the roof deck may need to be repaired so that it is structurally sound and up to standard. There are a couple of different types of structural roof deck which include:

⦁ Profiled metal sheeting

⦁ Timber or panel roofing

⦁ Concrete roofing

⦁ Composite metal deck

Single ply roof build up and the vapour control layer

The vapour control layer is the next layer to be added to a single ply roof, on top of the structural roof deck, when calculations have shown that an air and vapour control layer will be necessary. This layer is essential for controlling condensation, which is created by the rising warm air meeting the cool air at the top of the roof and condensing to form liquid on the surfaces. A vapour control layer can protect roof surfaces from this liquid, and prevent liquid from entering the roof structure and causing damage.

The most effective vapour control layers are flexible and non-decaying, offering the best longevity as well as maximum effectiveness. Because of this, the Sarnavap 500E is a vapour control layer we often use when creating a single ply roof system.

Single ply roof build up and the insulation layer

Another key aspect for any single ply roof build up is the insulation layer. This is essential for keeping your property thermally efficient and preventing the loss of warm air through the roof. The insulation layer is installed on top of the vapour control layer and can even be tapered to allow for a slight flat roof gradient, and to create falls for the flat roof. This is a great way to ensure proper runoff of rainwater and prevent standing water from building up on your flat roof.

For the insulation layer you can choose between tissue backed and foil backed insulation options, depending on the requirements of your property, and its use. We often work with 120mm tissue faced PIR insulation. This is a rigid thermoset insulation core, that is faced on both sides with a coated glass tissue facing, to offer a high level of performance.

The single ply membrane

Finally, the last layer to be added to a single ply roof is the single ply membrane itself. Fully waterproof, UV resistant and durable, a single ply membrane is designed to protect your roof from water and weather damage.

For high quality results we use Sika Sarnafil single ply membranes, selecting the perfect membrane for the project each and every time. Recent projects have included the use of:

⦁ Sarnafil G410-20EL single ply membrane

⦁ Sarnafil G410-15EL Fleeceback membrane

⦁ Sarnafil S327-15EL membrane

For more information or advice about single ply roofing for your commercial or industrial property, get in touch with the professionals today, here at Enviroply Roofing.